Turnkey Solutions

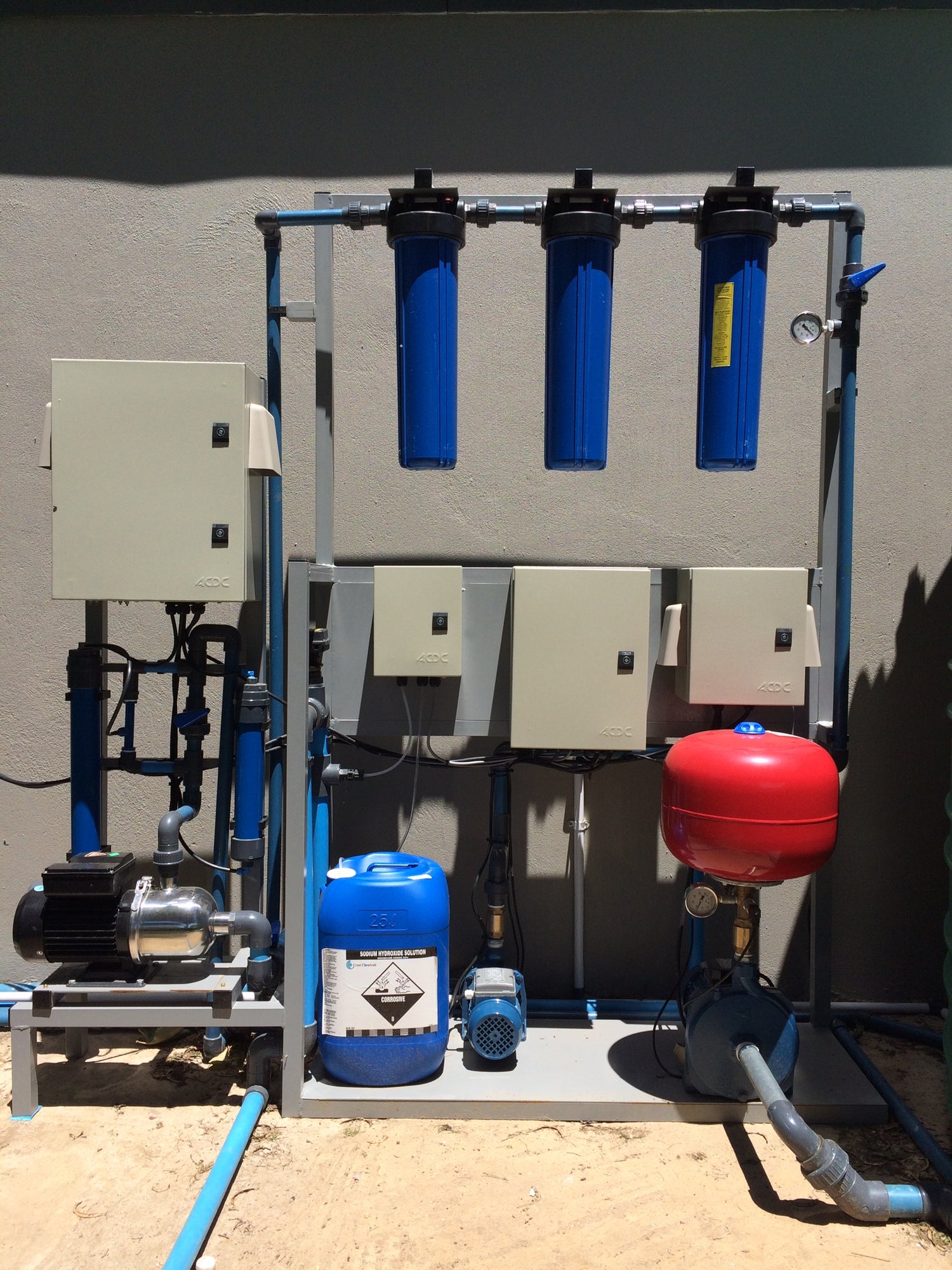

We cover the entire process from Borehole Drilling, Borehole Yield Test, Borehole Pump Installation, Water Analysis according to your needs and the Supply-Installation-Commission of your Water Treatment System

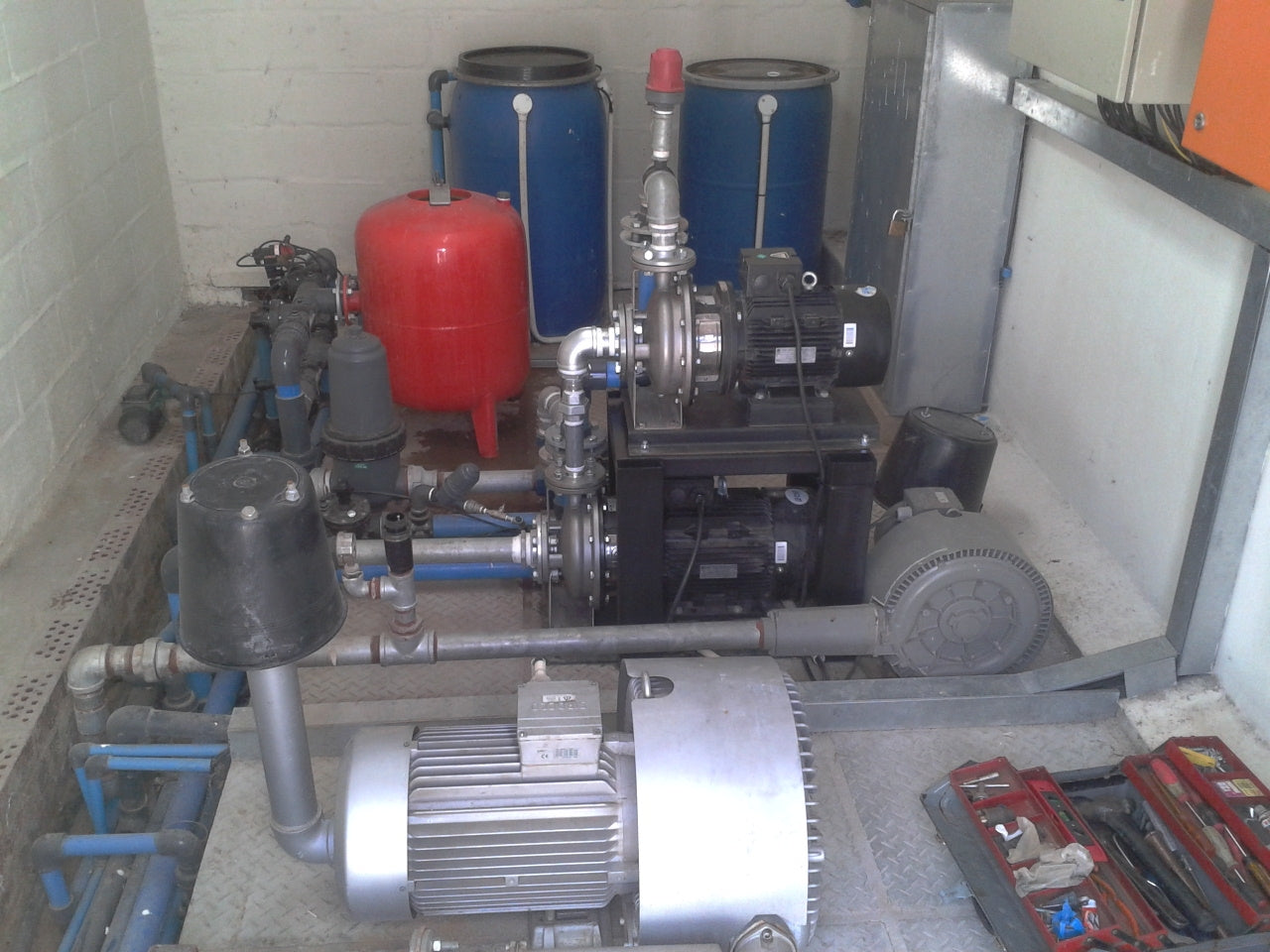

Borehole Pump Installation and Services

An Uninterrupted Water Supply is crucial if you have a Borehole. We ensure that your Borehole Pump is meticulously maintained to guarantee continuous operation. Should it need replacement, Our professional installation team is ready to provide prompt and efficient service.

Water Storage

Water is a precious resource and we are committed to assisting you to preserve it in high-Quality, durable Steel Reservoirs.

Operation and Services

Nothing lasts forever, and without proper maintenance, systems can degrade even faster. We specialize in Maintaining Existing Water Treatment Systems, Pumps, Filter Media and Pressure Vessels. Our Database allows us to give our clients a comprehensive Service Report and timely follow ups for future maintenance.

Operating in Complete Transparency and Offering Full Security to our Customers

Equilibrium Projects

Our Foundation: Customer Service. Our Buidling Blocks: Quality Products. Our Company Character: Reliable Service

Improtant Treatment Steps

Water Treatment Information

Sedimentation

Sedimentation: is the process of removing Suspended Material within your water source. Suspended Material has an impact on the Turbidity of your water. There are two types of Sedimentation (Plain Sedimentation) and (Chemically Enhanced Sedimentation)

- Plain Sedimentation: is when Suspended Materials naturally settle to the bottom such as Sand, Fine Sand and Silt

- Chemically Enhanced Sedimentation: This process requires extra steps to remove suspended material that does not naturally settle such as (Colloidal Particles, Bacteria, Algae, Clays, Colour ect). Coagulation, Flocculation and Clarification is the process that assists by reducing the (Turbidity) which is the murky, cloudy appearance of water by destabilizing the fine particles which then can settle out and be filtered.

Filtration

Filtration: Is the process of filtering out particles from water through filter media such as (Sand, AFM, Activated Carbon and Green Sand). This is also known as the Conventional Filtration Process. At this stage in the treatment chain, heavy metals, chlorine, pesticides, taste, odor, colour and other contaminants will be filtered out. This treatment process acts as a pre treatment before Softeners and RO Membranes. Turbidity is also further reduced that will make water become more aesthetically pleasing.

Filtration ensures the proper functioning of industrial processes that rely on clean water.

Disinfection

Disinfection: is the process of oxidizing or inactivating (Bacteria, Viruses and Protozoa). Bacteria such as E-Coli, Protozoa such as Cryptosporidium and Viruses such as Adenovirus are known as disease causing organisms or pathogens. Disinfection can be done through Chlorine, Ozone or UV.

Effective water disinfection not only ensures the safety of drinking water but also extends the shelf life of water stored in tanks and distribution systems. By using appropriate disinfection techniques, communities and industries can maintain a reliable supply of clean and safe water, preventing outbreaks of waterborne diseases and promoting overall health and well being.

pH Correction

pH Correction: is a crucial process that involves adjusting the pH level of water to a desired neutral range, typically between 6.5 - 8.5. This adjustment is essential for maintaining water quality and preventing issues such as corrosion, scaling and poor water taste. pH levels that are too high (alkaline) 9.5-14 or too low (acidic) 0-5.5 can damage plumbing systems, affect industrial processes and harm aquatic life.

In practical terms, pH correction can be achieved by adding chemicals such as acids to lower the pH or bases to raise it.

Iron Removal

Iron Removal: is a critical process aimed at eliminating excess Iron and Manganese from water, ensuring it meets safety and aesthetic standards. High Levels of Iron or Manganese in water can lead to various issues, such as staining laundry and clogging plumbing, unpleasant metallic taste and the proliferation of iron bacteria that cause slimy deposits and foul odors.

The process of Iron removal typically involves oxidation, where Iron and Manganese is converted from its soluble form to an insoluble form which can then be filtered out.

Softener System

Softener System: Are designed to remove excess minerals, primarily Calcium and Magnesium, which cause water Hardness. Hard Water can lead to various issues such as scale buildup in pipes and appliances, decreased efficiency of heating systems and reduced effectiveness of soaps and detergents.

Softener Systems use ion exchange resins to replace hardness minerals with Sodium and Potassium ions. The resin beads are charged with Sodium and Potassium. As Hard Water passes through the tank, the Calcium and Magnesium ions attach to the resin beads and are replaced with Sodium and Potassium ions, effectively softening the water.

By Installing a Water Softener System if you have Hard Water can prevent scale formation, extend the lifespan of plumbing and appliances. This leads to cost savings on maintenance and energy, as well as improved overall water quality for household or industrial use.

Reverse Osmosis

Reverse Osmosis: are advanced water purification devices that remove contaminants by forcing water through a semi-permeable membrane. This process effectively eliminates impurities such as dissolved salts, bacteria, viruses and other harmful substances resulting in high quality safe drinking water.

RO Systems are widely used in both Residential and Industrial settings

This process can remove up to 99% of dissolved salts (ions), particles, organic matter and other contaminants, making it one of the most thorough water treatment methods available.